01. Advanced Technology of Cool Running Heat-Reduction Paint

Patent No. 10-2089218

“Water-based pedestrian heat-reduction coating using magnesia concrete and its manufacturing method”

This section introduces the core technology of Cool Running heat-reduction flooring, designed to reduce urban heat-island effects and create safer, more comfortable pedestrian environments.

1) High-Performance Heat-Reduction Coating-Type Flooring

Advanced heat-reduction technology that effectively lowers surface temperatures even under intense solar exposure.

By utilizing highly durable premium heat-reduction pigments and high-reflectance special inorganic pigments, long-term heat-reduction performance is reliably maintained.

2) Slip-Resistance Performance Based on Magnesia Concrete

Slip resistance is maximized through the reaction properties of magnesia concrete.

Proprietary bead-type thermosetting resin–magnesia particles developed in-house ensure safe pedestrian traction even in rainy conditions and on sloped surfaces.

3) Eco-Friendly Water-Based Flooring Without Organic Solvents

A solvent-free, low-VOC (volatile organic compound) water-based system.

Designed with low odor and low irritation to protect worker health and improve on-site working conditions.

By reducing volatile organic compound emissions, it contributes to mitigating environmental pollution in industrial and construction environments.

02. Patent-Based Near-Infrared (NIR) Heat-Reduction Technology

This heat-reduction technology selectively reflects visible and near-infrared (NIR) wavelengths (750–1,250 nm), which carry the highest thermal energy in solar radiation, effectively lowering surface temperatures.

1) High-Performance Heat Reduction Without Conventional Heat-Reduction Pigments

Does not use conventional heat-reduction pigments such as hollow spheres, microspheres, or insulated fillers.

Heat-reduction performance is achieved through a proprietary combination of special inorganic pigments developed exclusively by SINA I&S.

2) Maximized Thermal Blocking Through High Near-Infrared Reflectance

Reflects high-energy wavelengths in the 750–1,250 nm range.

Directly blocks the portions of solar radiation that contribute most to surface temperature increase.

Temperature-reduction effects have been confirmed under real installation conditions.

3) Data-Driven, Verified Performance

Reflectance analysis based on the solar radiation spectrum.

High reflectance performance confirmed through near-infrared (NIR) spectroscopic testing.

03. What Sets Cool Running Heat-Reduction Paint Apart

Limitations of Conventional Heat-Reduction Paints

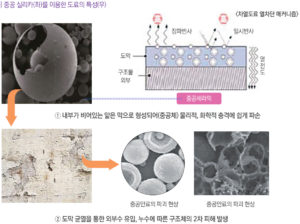

Conventional heat-reduction coatings based on hollow silica (microsphere) structures generally exhibit inherent structural weaknesses, resulting in limitations in long-term heat-reduction performance and durability.

Cool Running technology is a next-generation solution that fundamentally overcomes these structural issues.

1) Coating Damage Caused by the Structural Fragility of Hollow Particles

Hollow silica particles consist of thin shells with empty interiors,

making them highly susceptible to damage from external impact, moisture, and temperature fluctuations.

This vulnerability often leads to cracking, chipping, or peeling of the coating surface.

2) Secondary Structural Damage Due to Moisture Ingress

Moisture penetrates into the coating structure through surface cracks.

This intrusion can cause swelling, delamination, and the need for repainting, resulting in additional structural damage.

As a consequence, long-term maintenance costs increase.

3) Structural Causes of Heat-Reduction Performance Degradation

When hollow silica particles are damaged, the heat-reflection mechanism is weakened.

Over time, this leads to a rapid decline in thermal reflectance performance.

04. Conventional Heat-Reduction Paint vs. Cool Running Heat-Reduction Paint

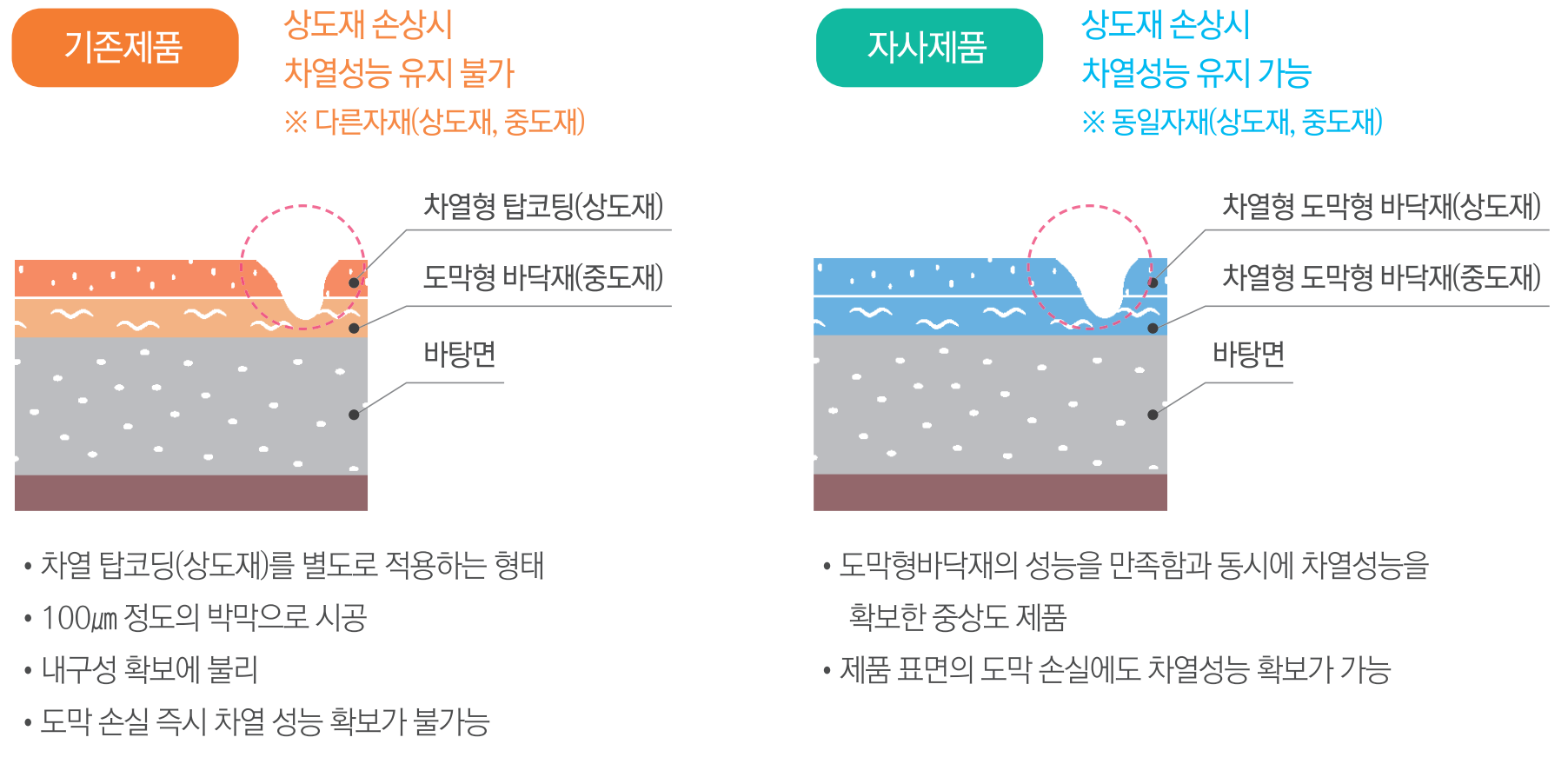

The key distinction lies in whether heat-reduction performance is maintained when the topcoat (surface layer) is damaged.

1) Conventional Heat-Reduction Paint

A structure in which heat-reduction performance is immediately lost even with minor damage to the topcoat

(due to the surface layer and intermediate layer being composed of different materials).

Issues

-

Requires a separate heat-reduction topcoat application.

-

Heat-reduction performance depends on a very thin top layer (approximately 100 µm).

-

Difficult to ensure durability; performance rapidly declines under external impact and abrasion.

-

Once the surface layer peels, the heat-reduction function is instantly lost.

2) Cool Running Heat-Reduction Paint (Our Product)

A structure in which heat-reduction performance is maintained even when the topcoat is damaged

(because the topcoat and intermediate layer are composed of the same heat-reductive material in a unified system).

Key Strengths

-

A monolithic structure in which the entire coating layer provides heat-reduction functionality.

-

Heat-reduction performance is sustained even with partial surface damage.

-

Excellent durability and stability, enabling easy long-term maintenance.

-

Performance remains effective over extended periods in real-world installation environments.